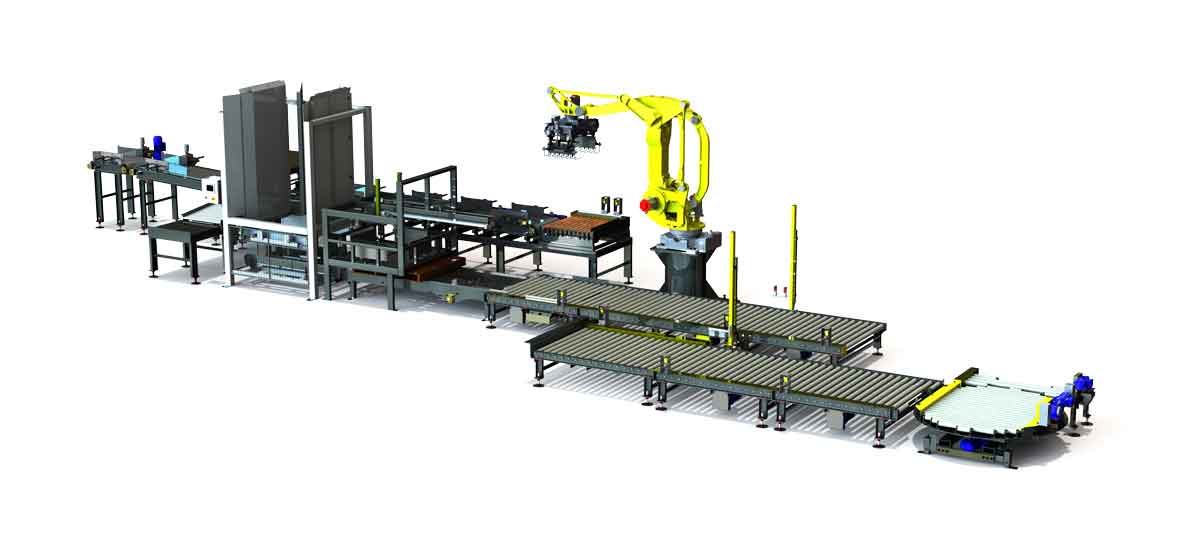

INDUSTRIAL BAG AUTOMATION & PALLETIZING

Automation that processes up to 10,000 bags per shift

Bag palletizing requires equipment that adapts to constantly changing conditions. Pellets, powder, cubes and granules each present distinct challenges from flow properties to moisture and bulk density variations. Our systems handle these environmental shifts while maintaining throughput, backed by end-of-arm tools engineered for 8 million cycles.

Our robotic palletizing systems handle multiple bag types from valve bags and open mouth to form fill seals and gusseted bags. Built-in bag cleaning systems remove excess product residue before stacking, while integrated flattening technology removes trapped air to create stable, compact loads.

If your line runs varying product sizes simultaneously, automatically adjustable tooling can handle variable sizing without manual changes, with bundle tool attachments that switch over in under 60 seconds. This flexibility can deliver up to 12,000 bags per shift. For higher volumes, our hybrid layer-forming systems process full layers at 120 bags per minute.

Every critical component moves from raw material to finished system under one roof. Single-source manufacturing delivers reliability you can’t get from assembled components.

Capabilities

- Robotic bag palletizer handles 5, 7, and 10-lb bags at speeds up to 64 per minute

- Handles 50-lb bags at up to 27 bags per minute

- Layer-forming systems process up to 120 bags per minute

- Integrated bag cleaning and flattening systems

- Bundle tool changeover completed in under 60 seconds

- In-motion check weighing, metal detection and reject handling