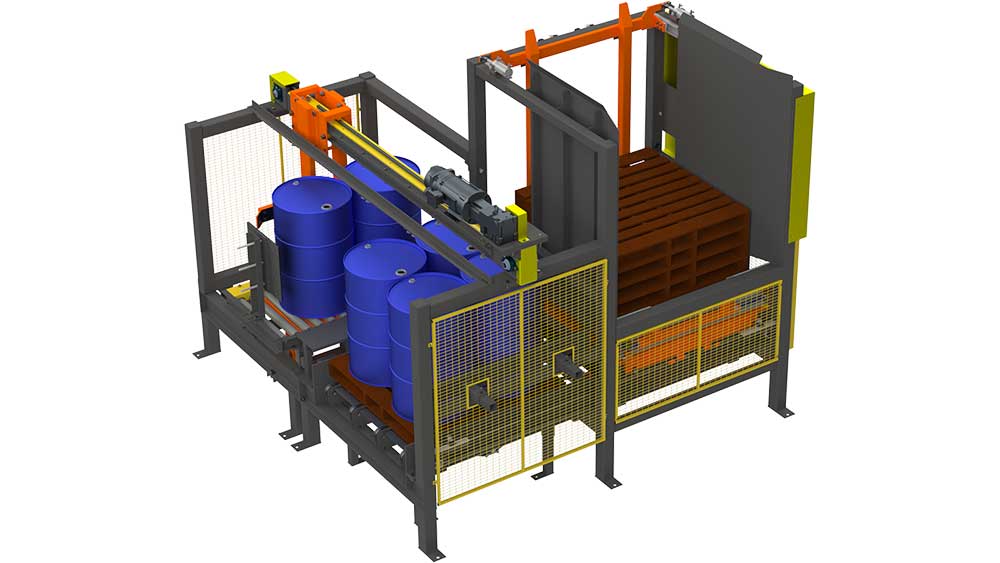

AUTOMATED DRUM PALLETIZING & HANDLING

From manual lifting to automated precision

Drums present unique handling challenges. A single production line often runs multiple container sizes from 15-gallon to 55-gallon drums. Traditional automation struggles with this variation, forcing frequent changeovers that slow production.

Our conventional systems excel in classified environments and deliver higher speeds for uniform loads. When running single-size containers like 15-gallon drums with nine per layer, conventional systems achieve faster cycle times. They’re particularly effective for hazardous environments requiring Class-rated equipment.

Our robotic systems handle your complete container range without tool changes. The robotic drum palletizers handle 55-gallon drums and pails of any size simultaneously, delivering consistent throughput across your full container range. We manufacture every critical component in-house, from end-of-arm tooling to control systems, ensuring reliable operation in any environment – caustic, explosive or temperature-extreme.

From those first machines to today’s advanced systems, we’ve maintained one constant: building drum handling equipment that lasts decades, not years. When you need a system that delivers reliable performance year after year, we have the engineering experience to make it happen.

Capabilities

- Empty drum handling (55, 30, 15 gallon sizes and beyond)

- Full drum handling (55, 30, 15 gallon sizes and beyond)

- Conventional and robotic palletizing solutions

- Rotation features for drum positioning

- Specialty conveyors for floor space optimization

- Additional optional handling features available