Frequently Asked Questions

Can a keg palletizer be customized for specific brewery needs?

Yes, PASCO's keg palletizers can be customized to meet the specific needs of individual breweries, ensuring efficient and precise keg handling tailored to their operations.

What types of keg handling equipment are commonly used in breweries?

The types of keg handling equipment commonly used in breweries include automated keg palletizers, depalletizers, and conveyor systems designed to efficiently move and stack kegs in a wet brewing environment.

How does a keg palletizer increase packaging efficiency?

A keg palletizer increases packaging efficiency by automating the process of stacking and loading kegs onto pallets, allowing for faster and more consistent handling compared to manual methods.

What safety features do keg palletizers typically include?

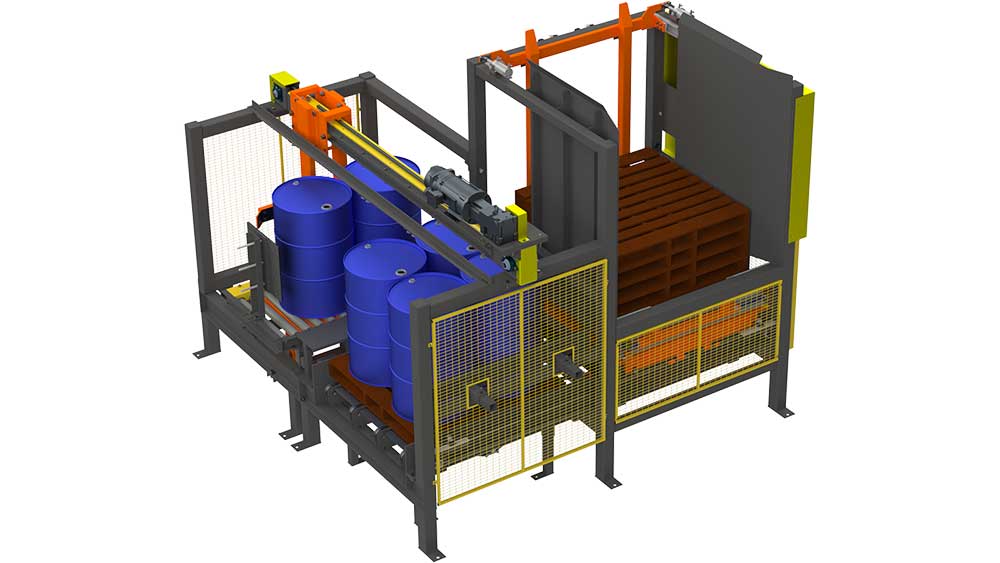

Keg palletizers typically include safety features such as emergency stop buttons, guarding around moving parts, and sensors to detect obstacles or worker presence for safe operation in a wet brewing environment.

What are the benefits of automated keg palletizing?

The benefits of automated keg palletizing include increased efficiency, improved worker safety, and consistent handling of kegs in a wet brewing environment. Automated systems can accurately and quickly palletize kegs of varying sizes.

How does a keg palletizer reduce labor costs?

A keg palletizer reduces labor costs by automating the process of stacking and organizing kegs onto pallets, eliminating the need for manual labor and streamlining the keg handling workflow.

What is the function of a keg palletizer in a brewery?

The function of a keg palletizer in a brewery is to automatically stack and organize kegs onto pallets, improving efficiency and reducing manual labor in the keg handling process.

What customization options exist for keg palletizers?

The customization options for keg palletizers include adjustable pallet patterns, keg size accommodations, and automated control systems to optimize handling for various brewing environments and keg requirements.

How do keg handling systems improve workflow?

Keg handling systems improve workflow by automating the process of moving and managing kegs, increasing efficiency and reducing manual labor in brewing operations.

What are the key features of keg handling equipment?

The key features of keg handling equipment include precision controls, automation, and adaptability to various keg sizes in wet brewing environments, enabling efficient and streamlined keg handling operations.

What is the lifespan of a keg palletizer?

The lifespan of a keg palletizer depends on factors such as usage, maintenance, and operating environment, but with proper care and maintenance, a well-designed keg palletizer can have a lifespan of 25 years or more.

How do keg palletizers accommodate different keg shapes?

Keg palletizers accommodate different keg shapes through adjustable gripping mechanisms, sensors, and programmable controls that can adapt to handle a variety of keg sizes and styles in a brewing environment.

What training is needed for operating keg equipment?

Operating keg equipment requires specialized training to ensure proper handling, maintenance, and safety procedures. Operators should receive comprehensive instruction on the system's functionality, control mechanisms, and maintenance protocols to effectively manage the automated keg handling process.

How do keg handling systems ensure safety compliance?

Keg handling systems ensure safety compliance by incorporating features such as automated controls, sensor-based monitoring, and ergonomic designs to minimize manual handling and reduce the risk of injuries during keg transportation and storage.