AUTOMATED VALVE BAG FILLING

Engineered for your exact product requirements

Our valve bag filling systems maintain precise target weights across all materials from fine powders to granular products to concrete. We match filling technology to your specific material properties, eliminating variations in fill weight and cycle time.

PRECISION-MATCHED TECHNOLOGY

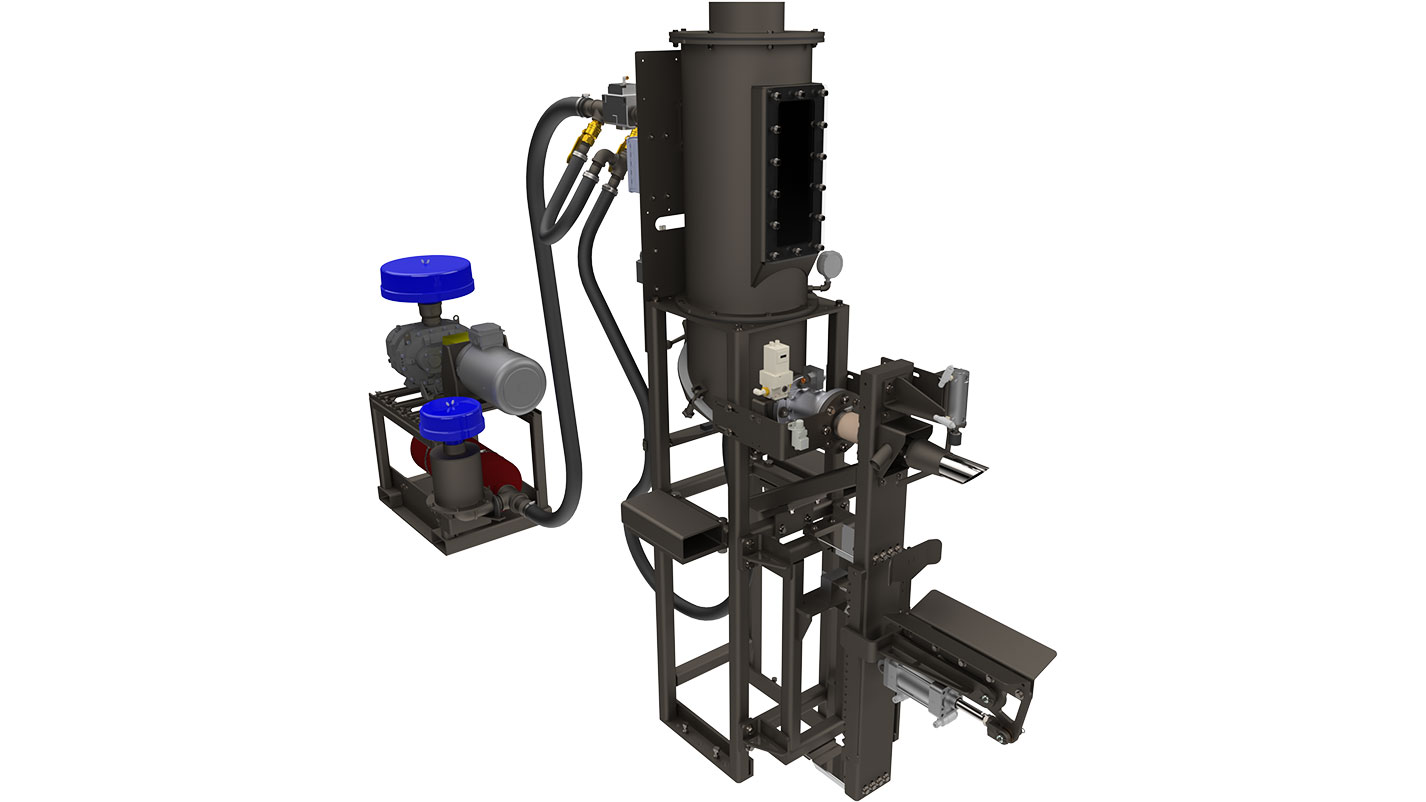

Material-specific valve bag filling systems

Filling technology is selected based on material behavior. Air-powered systems fluidize concrete and aggregates, impeller drives control fine powders, and auger feeds meter precise portions. Product testing confirms the most accurate approach at the required production rate.

FILL-WEIGHT CONTROL SYSTEMS

Verified weight accuracy every cycle

Electronic load cells or mechanical scale beams monitor every fill in real time. Once target weight is reached, automated controls stop product flow immediately. The result is consistent, documented accuracy without manual weight checks or rework.

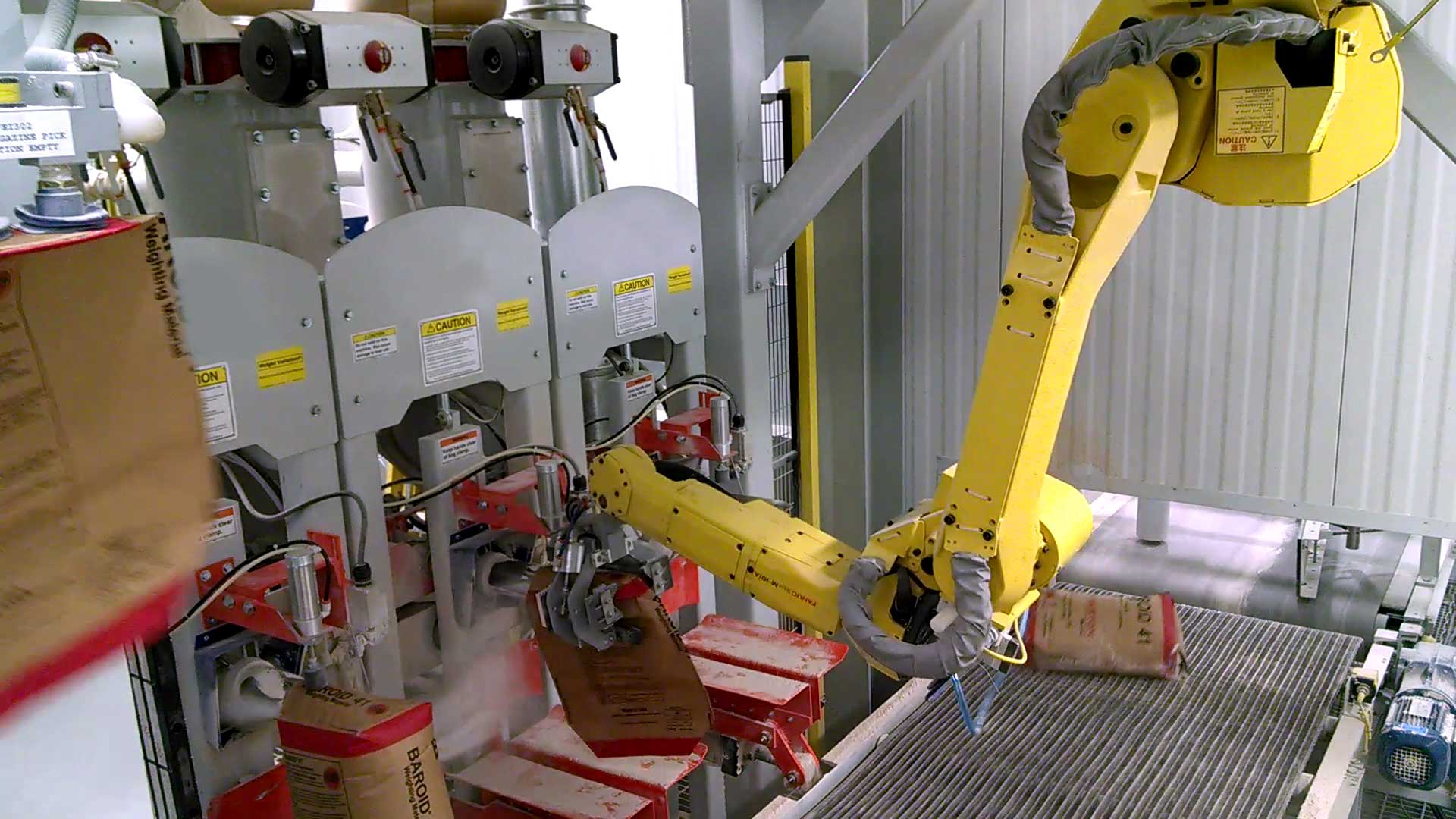

COMPLETE LINE AUTOMATION

From empty valve bag to pallet

Valve bag fillers integrate with PASCO® valve bag placers and robotic palletizing systems for a fully automated line. Unified controls synchronize placement, filling, and palletizing, eliminating handoffs between vendors and keeping production consistent under a single support partner.

CAPABILITIES

- Multiple filling technologies (air, impeller, auger)

- Electronic load cell accuracy

- Real-time weight monitoring

- Automatic product flow control

- Complete line automation (placement, filling, conveying, palletizing)

- 24/7 service and technical support