Selecting the ideal palletizing solutions partner

Turning manual stacking into a reliable, automated process is one of the fastest ways to improve throughput, reduce costs, and reduce repetitive, injury-prone labor. Companies facing labor shortages, damaged product or bottlenecks at the end of the line see immediate gains when they bring in an experienced palletizing automation partner. Automated palletizers not only solve labor challenges but also improve consistency in stacking, load stability and shipping accuracy, factors that directly impact customer satisfaction and supply chain performance.

This guide covers how integrators design both robotic and conventional palletizing systems—from custom end-of-arm tooling to HMI integration—and the roles OEMs and system integrators play in making those systems run smoothly.

The advantages of working with a partner

Working with a palletizing solutions provider means more than just installing a machine. A good partner engineers a palletizer around your operation, integrates it with your conveyors and controls, and supports it long after startup. That expertise keeps downtime low, product moving and throughput high. With the right robotic palletizer or automated palletizer in place, efficiency gains are visible from day one, delivering a faster return on investment.

How to choose the right palletizing solutions partner

The best provider combines proven technical expertise, strong service capabilities and a history of innovation. It’s also important to understand whether you’re working with a system integrator or an Original Equipment Manufacturer (OEM).

While both system integrators and OEMs play vital roles in automation, their core functions differ significantly:

- System integrator – Focuses on bringing together components from different manufacturers, building complete palletizing systems around your needs. They often work across multiple robot brands, control systems, and conveyor types to deliver the best fit.

- Original Equipment Manufacturer (OEM) – Designs and builds their own palletizing equipment in-house. This means deep product knowledge, direct control of parts and faster turnaround when something needs to be replaced or customized.

When selecting a partner, consider whether your needs are best met by a specialist in a particular type of equipment (OEM) or by a company that can orchestrate a broader range of technologies to create a comprehensive solution (System Integrator). The strongest providers operate as both, combining in-house manufacturing with integration expertise.

Experience and industry knowledge matter

A seasoned palletizing partner should demonstrate:

- Decades of successful installs solving complex challenges in real plants.

- Partnerships with leading robot brands (FANUC, ABB, Kawasaki, Yaskawa).

- Industry-specific knowledge in food and beverage, building products, ice and more, where safety and compliance are critical.

Proven experience means fewer surprises during installation and faster ramp-up once your system goes live. A provider that understands your industry can anticipate common challenges, design around them and ensure the palletizer is reliable from day one.

This experience ensures your palletizing solution will not only run reliably but also meet every regulatory and production requirement.

Customization and support you can count on

Every plant is different. That’s why the best providers deliver:

- Custom tooling and software to best palletize your product mix.

- Preventive maintenance and diagnostics to increase uptime.

- Parts management to keep replacements on hand and lines moving.

- Real-time, human support so if things go wrong, downtime is minimized.

Support is what makes automation a long-term investment instead of just a machine.

Innovation and integration for growth

Future-ready palletizing solutions require flexibility and a focus on new technology:

- Integration flexibility with existing equipment and PLCs.

- Advanced vision and IoT for smarter product handling, predictive maintenance and stronger load stability.

- Scalable modular designs to add robots, components or conveyors as your operation grows.

These innovations make sure your palletizing system stays competitive as tech advances.

Types of palletizing systems

Providers typically offer:

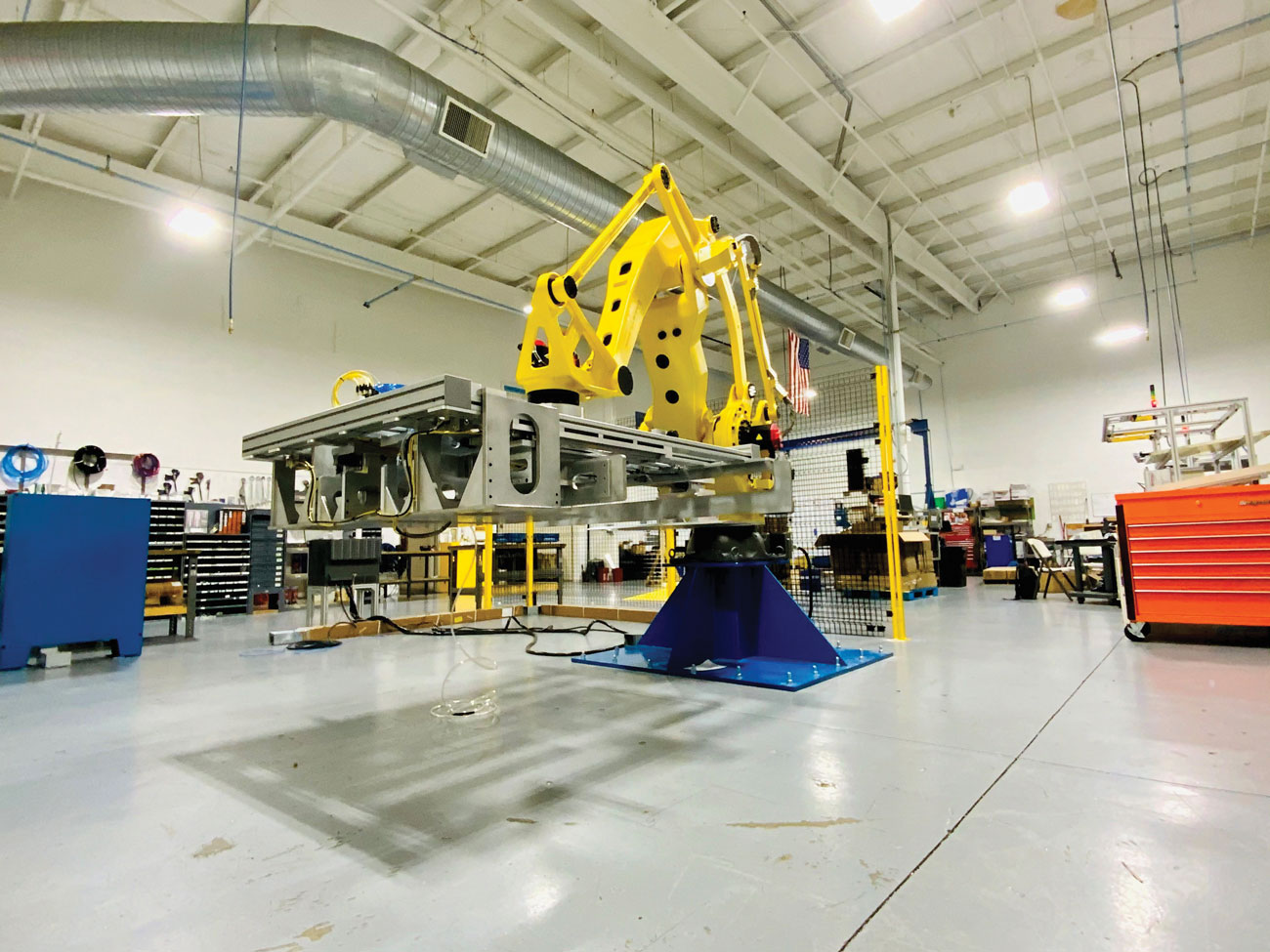

- Robotic palletizers – High-speed, precise stacking across a wide range of packaging types. Versatile and practical.

- Conventional palletizers – High-speed stacking for low mix, high volume loads.

- Collaborative robotic palletizers (cobots) – Safe, compact and easy-to-deploy palletizing cells for lighter payloads working alongside an operator.

- Custom end-of-arm tooling – Tooling that attaches to a robotic arm to handle a task or packaging type.

ROI you can measure

The right partner will help you quantify ROI up front:

Why partner with PASCO

At PASCO, we design, engineer, manufacture and support palletizing systems in-house — both robotic and conventional. With decades of experience and a proven track record across industries, we deliver systems that integrate seamlessly with your line, run reliably and drive measurable ROI.

- Custom design for your products, facility and throughput.

- Seamless integration with your existing equipment and upstream processes.

- Dedicated support from our team through the system’s full lifecycle.

Your end-of-line shouldn’t be a bottleneck. It should be an advantage.

Unlock your production potential

Choosing a palletizing partner is a decision that affects every part of your supply chain. It’s not just about adding equipment—it’s about working with a team that knows your challenges and has the experience to build solutions that last. The right provider brings advanced technology backed by hard-earned industry knowledge, making sure your investment delivers efficiency, lowers costs, and strengthens your competitive position. Your end-of-line doesn’t have to slow you down. With the right partner, it becomes a driver of growth, reliability, and long-term success.