Palletizing automation comes in many forms, from massive industrial systems to flexible collaborative robots. But which solution makes sense for your operation?

This FAQ answers the most common questions about palletizing automation options to help you make an informed decision.

Getting started with palletizing automation

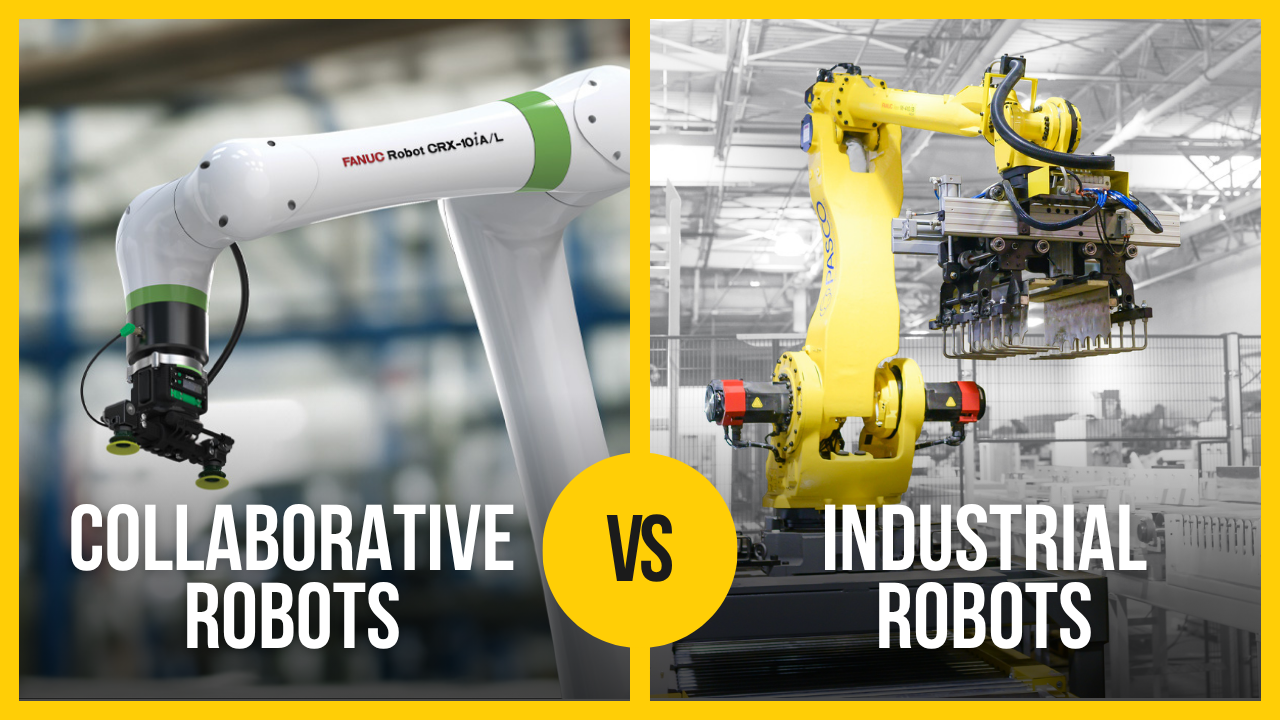

What is the difference between a collaborative and an industrial robot for palletizing?

An industrial robot is built for strength, speed and high-payload applications. It typically requires more space and safety fencing but delivers maximum throughput.

A collaborative robot (or cobot) works safely alongside people and is easier to integrate into existing operations. However, its limitations in speed and payload often make it a better fit for light-duty palletizing.

How do I know if a cobot palletizer is right for my manufacturing operation?

It depends on four factors:

- Production speed – A cobot handles 6–10 cycles per minute

- Payload capacity – Most cobots handle net payloads of up to 66 pounds including tooling

- Available space – A cobot requires minimal floor space without safety fencing

- Production flexibility – A cobot works best when products or patterns don’t change frequently

A cobot palletizer works well in low-volume, low-variability environments. For higher throughput or growing operations, an industrial palletizing robot is the better choice.

What types of businesses benefit most from cobot palletizing systems?

A cobot delivers results for:

- Small to mid-sized manufacturers with moderate production speeds

- Operations with space constraints where an industrial robot won’t fit

- Companies facing labor challenges and needing rapid implementation

Most palletizing applications, especially those involving heavier loads, multiple shifts or variable SKUs are better served by an industrial robotic palletizing system.

When cobots make sense for palletizing

How fast can a cobot palletize products compared to industrial robots?

A cobot handles up to 10 cycles per minute in non-collaborative mode for palletizing applications. An industrial robot handles up to 30 cycles per minute with greater consistency across shifts.

What is the maximum weight a cobot can lift when palletizing?

Most cobots designed for palletizing handle net payloads up to 66 lbs., making a cobot suitable for:

- Consumer packaged goods

- Food and beverage cartons and cases

- Pharmaceutical products

- Light industrial components

Heavier products require an industrial palletizing robot with higher payload capacities.

How much floor space is needed for a cobot palletizing cell?

A cobot palletizing cell needs only the space of 2–3 pallets and doesn’t require extensive safety fencing. This compact footprint works well for a facility with limited floor space or an operation looking to integrate automation into existing workflows without major layout changes.

How long does it take to install and program a cobot palletizer?

Most cobot systems can be operational within 2–3 days from delivery. This rapid deployment helps a manufacturer address immediate labor challenges or production bottlenecks.

Short install times, however, don’t always translate to long-term suitability especially in higher-volume environments.

When industrial robots are better for palletizing

When should I choose an industrial robot over a cobot for palletizing?

An industrial palletizing robot is the better choice when:

- Production exceeds 10 cycles per minute

- Net payload requirement is more than 66 pounds

- Palletizing height exceeds 6 feet

- Dedicated automation space is available

- Product patterns or SKUs change frequently

These criteria apply to the majority of palletizing operations.

What industries can’t use cobots for palletizing?

An industrial palletizing robot is necessary in high-volume, heavy-duty facilities such as:

- Building products manufacturing

- Chemical and agricultural products

- Food and beverage distribution centers requiring maximum speeds

- Heavy industrial components manufacturing

- Operations running at maximum speeds 24/7

In these environments, a cobot often falls short in performance, durability and throughput.

Are cobots durable enough for harsh manufacturing environments?

An industrial palletizing robot offers better protection against harsh conditions like extreme temperatures, dust, or corrosive environments. Its sealed components and robust construction make it well-suited for challenging settings where durability is essential.

A cobot is better suited for clean, climate-controlled industrial environments.

Safety and implementation

Do cobots for palletizing require safety fencing like industrial robots?

Not in most palletizing applications. A cobot uses force-limiting technology that stops movement when resistance is encountered, allowing it to work safely alongside human operators without traditional safety fencing.

However, depending on:

- The weight and type of product being palletized

- The end-of-arm tooling being used

- The speed of the palletizing operation

- The facility’s specific safety requirements

…a proper risk assessment may still recommend additional safety measures for the palletizing cell.

Business considerations

What is the ROI timeframe for a cobot palletizing system?

Most companies see full payback within 12–18 months for a cobot palletizing system.

Factors that can accelerate ROI include:

- Multi-shift operation

- High labor turnover in manual palletizing roles

- Ergonomic risks from manual lifting

- Applications requiring consistent pallet quality

ROI can diminish quickly if production needs grow beyond what a cobot palletizer can handle.

How does the total cost of a cobot palletizer compare to industrial robots?

Consider the following when evaluating total cost of ownership:

- Initial purchase – A cobot palletizer often costs 50–70% less than an industrial system

- Implementation – Installation typically costs 25–40% less

- Facility modifications – A cobot rarely requires structural changes

- Programming – Programming costs are minimal

- Maintenance – Cobots have fewer components requiring service

- Power usage – Cobots consume significantly less electricity

An industrial palletizing robot costs more upfront but typically delivers better long-term economics for high-volume or demanding applications. A cobot offers a lower entry point, but that comes with performance trade-offs.

How do cobots affect existing palletizing staff and workforce planning?

A cobot typically complements existing staff, allowing an operator to supervise rather than manually palletize. This reduces ergonomic strain and improves consistency without removing the human element.

An industrial robot may fully automate the task, freeing up workers for other responsibilities like quality control, logistics, or equipment oversight.

Maintenance and support

What maintenance is required for a cobot palletizing system?

A cobot palletizer typically requires:

- Quarterly inspections of mounting points and joints (15–30 minutes)

- Gripper checks for wear (as needed)

- Annual service check by a technician (recommended)

- Occasional software updates

For operations where uptime is critical, an industrial palletizing robot may offer longer service intervals and greater system durability.

Can a single cobot palletize products onto multiple pallet positions?

Yes. Many cobot palletizing cells are designed with multiple pallet positions. This configuration allows:

- Continuous operation while one pallet is being replaced

- Sorting of different product types

- Mixed-order palletizing for custom shipments

- Higher throughput without pausing for pallet exchange

That said, performance is still limited by the cobot’s cycle speed and payload capacity.

Making the right choice

Collaborative robots have opened new doors for automation, offering flexible, low-footprint solutions that are easy to deploy and operate. But when it comes to palletizing, the demands of speed, payload, and uptime often exceed what a cobot is built to handle.

For a manufacturer with light, low-volume applications and limited space, a cobot palletizer can be a practical first step.

For everyone else, especially operations expecting growth, variability or round-the-clock performance, an industrial robot remains the more capable and future-proof choice.

Choosing the right palletizing solution starts with understanding your current needs and planning for where you’re headed next.

Image shown of Fanuc CRX Collaborative Robot and Fanuc M-410 Series Industrial Robot