AUTOMATED PALLETIZING SOLUTIONS

Palletizing systems built for your production environment

Our palletizers deliver stable loads the first time, every time across hot, cold, damp, abrasive and explosive-rated environments. As an authorized system integrator for FANUC, ABB, Kawasaki and Yaskawa robotics, we deliver automation solutions that match your exact requirements. Drawing from 5 decades of solving real production challenges, we solve what manual palletizing can’t.

PALLETIZING SYSTEMS FOR ANY ENVIRONMENT

Built to match your line requirements

Our palletizing systems are engineered around documented line speeds, available floor space, and real throughput targets. Robotics selection, layout and programming are based on how your line actually runs.

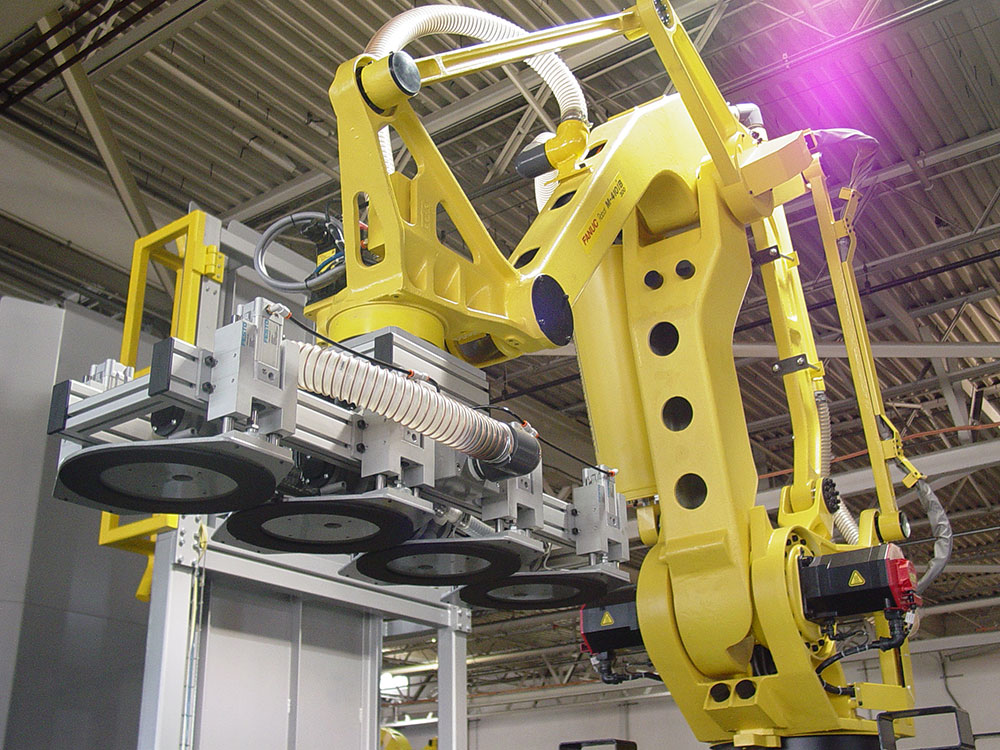

CUSTOM END-OF-ARM TOOLS (EOAT)

Tooling precision-engineered for your products

All end-of-arm tooling is designed, engineered and manufactured in-house. Our EOATs routinely exceed 5 million cycles before overhaul. And because we’re the OEM, long-term support, service and rebuilds stay straightforward.

PURPOSE-BUILT STANDARD FEATURES

Standard features others call upgrades

Every PASCO® palletizer includes pallet centering and HMI-controlled pattern adjustment as standard. While other manufacturers treat these essentials as add-ons, we engineer them into every system because consistent production can’t be optional.

CAPABILITIES

- Conventional palletizing systems

- Industrial or collaborative robotic palletizing systems

- High-speed bag, case, pail and drum palletizing

- Custom end of arm tooling

- Automatic end of arm tool changer

- Pallet conveyor integration

- Integrated slip sheet placement

- Integrated pallet dispensing

- Integrated check weighing

- Integrated reject handling

- 1-year warranty with buyback guarantee

- Integration into existing operations